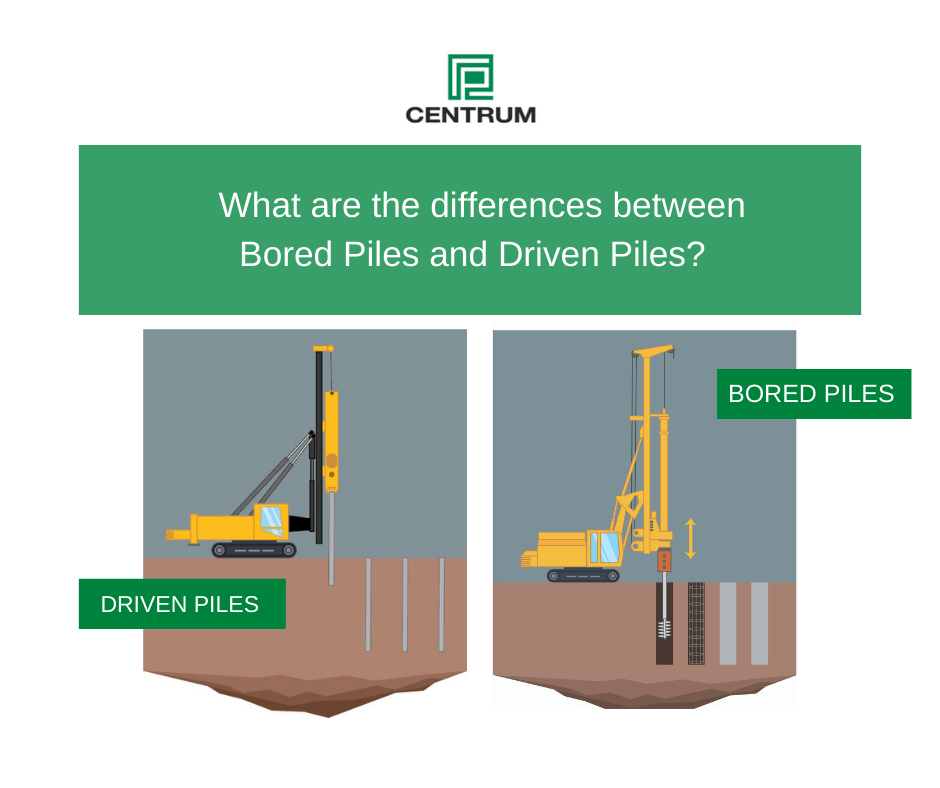

What are the differences between Bored Piles and Driven Piles?

The fundamental difference between a driven pile foundation and bored pile foundation lies in their point of manufacture. A driven pile is formed off-site under factory-controlled conditions and a bored pile is manufactured on site and in place.

Bored pile foundations, also known as replacement piles, are typically poured in place and provide support for structures, transferring their load to layers of soil or rock that have sufficient bearing capacity and suitable settlement characteristics. Driven piles are sometimes referred to as displacement piles because in the process of driving the pile into the ground, soil is moved radially as the pile shaft enters the ground. There may also be a component of movement of the soil in the vertical direction.

Material

Driven Piles are made from preformed material having a predetermined shape and size that can be physically inspected prior to and during installation, which is installed by impact hammering, vibrating or pushing into the earth. These may include timber, steel, or precast concrete piles.

Bored Piles are cast-in-place concrete piles, meaning the pile is cast on the construction site. These may include Drilled Shafts, Mini Piles, Micro Piles, Drilled Displacement, Sectional Flight Auger (SFA) and Continuous Flight Auger (CFA) piles.

Equipment

Driven Pile Construction Equipment typically includes a crane, hammer, piling rig, powerpack (hydraulic or air-hammer and Bored Piles typically utilise a Drill Rig, Helper Crane, Spoil Handling (loader, skip pan, etc.), casing, slurry handling, cage erection template, concrete truck and concrete pump truck.

Bored Pile Advantages

The main advantages of bored piles include:

- Piles of variable lengths can be extended through soft, compressible, or swelling soils into suitable bearing material.

- Piles can be extended to depths below frost penetration and seasonal moisture variation.

- Large excavations and subsequent backfill are minimized.

- Less disruption to adjacent soil occurs.

- Vibration is relatively low, reducing disturbance of adjacent piles or structures.

- For many design situations, bored piles offer higher capacities with potentially better economics than driven piles.

Driven Pile Advantages

The main advantages of driven piles include:

- Piles can be precast to the required specifications.

- Piles of any size, length and shape can be made in advance and used at the site. As a result, the progress of the work will be rapid.

- A pile driven into granular soil compacts the adjacent soil mass and as a result the bearing capacity of the pile is increased.

- The work is neat and clean. The supervision of work at the site can be reduced to a minimum. The storage space required is very much less.

- Driven piles may conveniently be used in places where it is advisable not to drill holes for fear of meeting ground water under pressure.

- Driven pile are the most favoured for works over water such as piles in wharf structures or jetties.

Find out more about Driven Piles by downloading our postcard

If you’re looking for a pre-cast pile supplier, please get in touch by calling 0163615700 or by emailing Paulpendleton@centrumpile.co.uk

Centrum Pile Ltd

Hawton Lane, Newark-on-Trent, Newark, Nottinghamshire NG24 3BU

Tel: 01636 615700

Email Address: info@centrumpile.co.uk

Other Centrum Locations